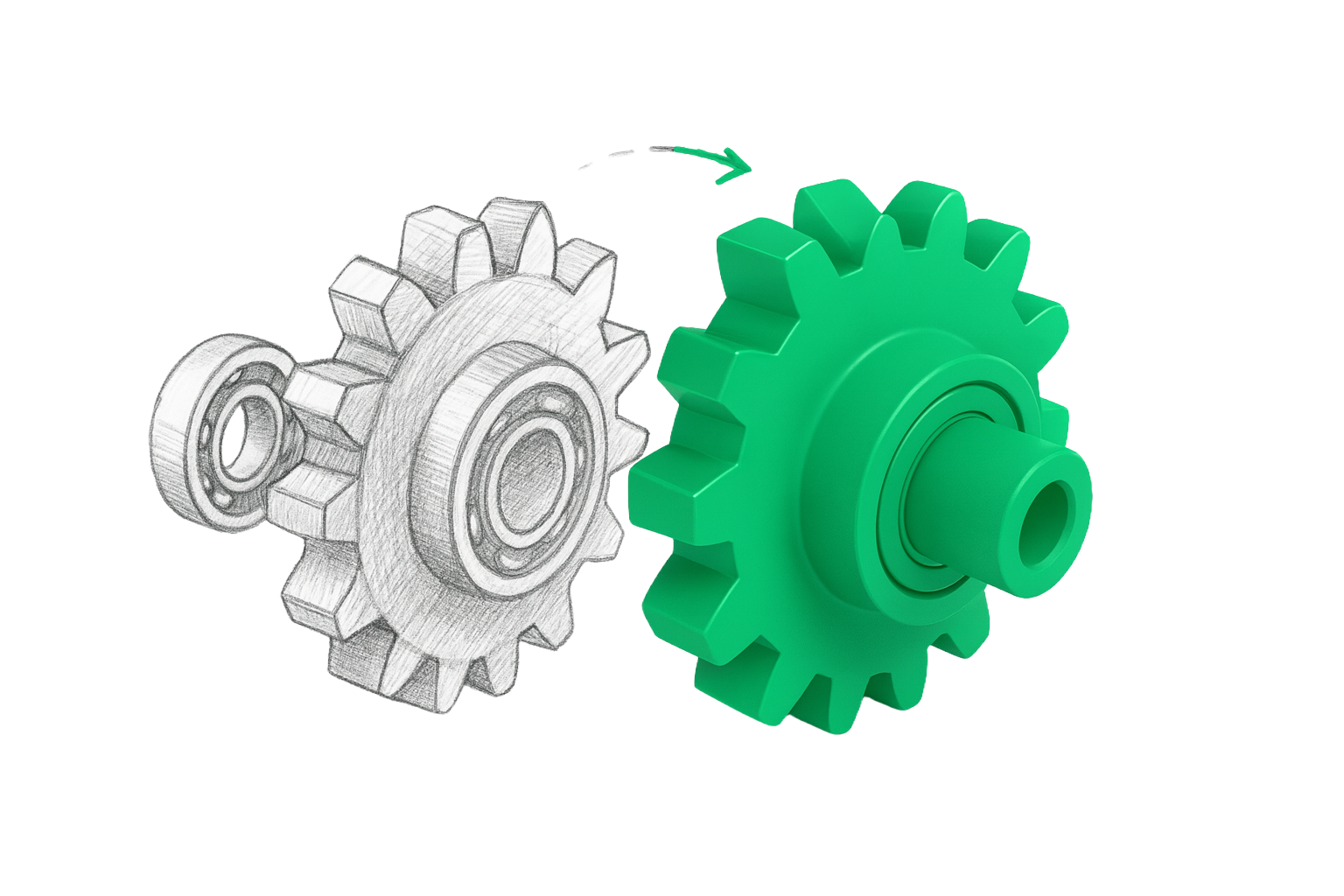

Reverse Engineering & Spare Parts (Industry)

Reverse engineering and manufacturing of spare parts for industrial machines

1Challenge

An industrial company needed to manufacture spare parts for older production machines where the manufacturer no longer provided service. Original documentation was not available and some parts were damaged or missing. The requirement was to create accurate CAD models, verify functionality, and manufacture spare parts in various materials including stainless steel and special alloys.

2Solution

We performed 3D scanning of existing parts using precise scanners. We created detailed CAD models with tolerances according to functional requirements. For missing parts, we used reverse engineering based on function analysis and context within the entire machine. We created prototypes using 3D printing to verify dimensions and functionality before final production. Final parts were manufactured using CNC machining and other technologies according to material and precision requirements.

3Results

We successfully created precise spare parts for 15 different components. All parts passed functional testing and were deployed into operation. The client saved costs on purchasing new machines and extended the lifespan of existing equipment. We also delivered complete documentation for future production.